Rubber ducks are more than just bath-time toys—they’re the result of a precise and fascinating manufacturing process.

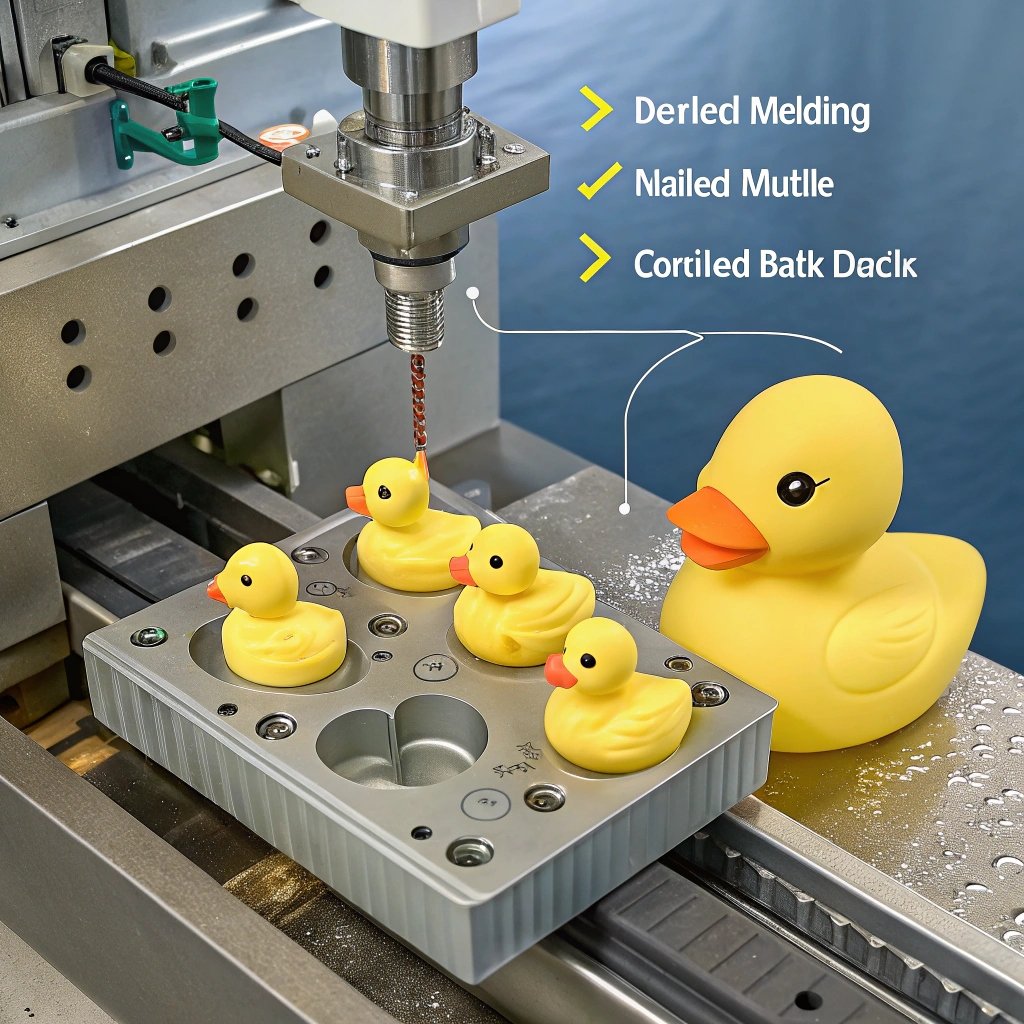

Rubber ducks are typically manufactured using injection molding[^1], a process where molten rubber is injected into molds to form the desired shape.

What Is the Manufacturing Process of Rubber Molding?

Rubber molding for ducks primarily uses injection molding[^2], where heated rubber is injected into molds to form the duck shape.

Key Steps in Rubber Molding:

- Material Preparation: Raw rubber is mixed with additives to enhance flexibility and durability.

- Injection Molding: Rubber is heated and injected into pre-designed molds.

- Cooling and Ejection: The molded duck is cooled and removed from the mold.

- Finishing: Excess material is trimmed, and paint or details are applied.

What Is the Rubber Ducky Method?

The rubber ducky method involves explaining code line-by-line to an inanimate object[^3] to identify bugs.

How It Works:

- Explain Your Code: Walk through each line aloud.

- Identify Issues: Talking through logic exposes mistakes.

- Clarify Thinking: Forces clear articulation of problems.

What Is the Manufacturing Process of Rubber Hose?

Rubber hoses are commonly produced through extrusion[^4], where rubber is shaped into a continuous profile.

Manufacturing Steps:

- Compounding: Mixing raw rubber with fillers and stabilizers.

- Extrusion: Rubber is forced through a die to create shape.

- Curing: The extruded rubber is vulcanized for durability.

- Finishing: Cutting, inspecting, and adding fittings.

What Is Rubber Duck Engineering?

"Rubber duck" engineering refers to wheeled excavators nicknamed for their rubber tires and duck-like shape[^5].

Characteristics:

- Mobility: Rubber tires allow travel on roads.

- Versatility: Operates in urban and rural sites.

- Efficiency: Quick to reposition without transport trucks.

How Long Do Rubber Ducks Last?

Typically, rubber ducks can last several years[^6], but exposure to sunlight and harsh conditions may degrade them faster.

Factors Affecting Longevity:

- Material Quality: Better rubber resists cracking.

- Environmental Exposure: UV light accelerates breakdown.

- Usage: Frequent squeezing or bending wears material.

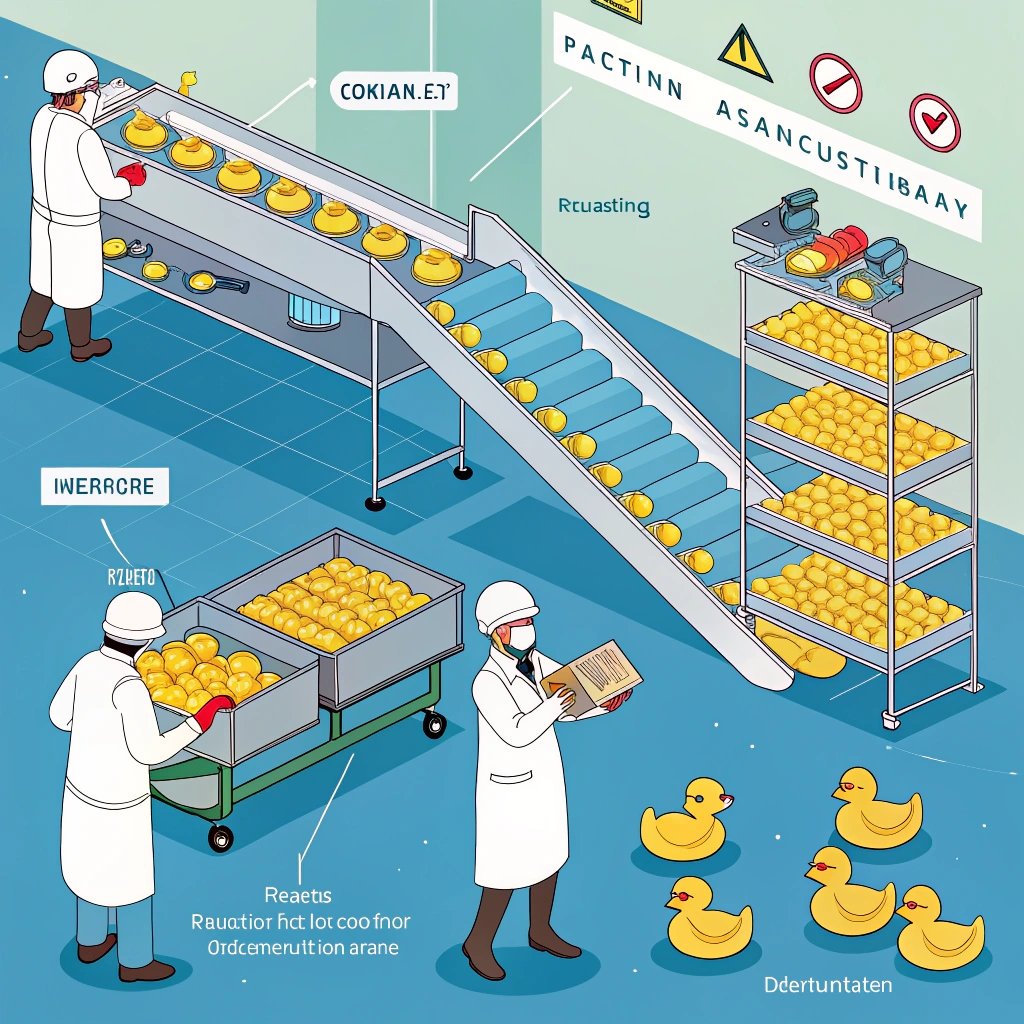

What Is the Process of Manufacturing Rubber?

The process includes harvesting latex, compounding, shaping, and vulcanization[^7] to produce durable rubber items.

Manufacturing Stages:

- Latex Collection: Extracting sap from rubber trees.

- Compounding: Adding pigments, sulfur, and fillers.

- Shaping: Using molds or extrusion.

- Vulcanization: Heating with sulfur to strengthen.

What Are the Four Methods of Processing Rubber?

The four primary methods are extrusion, molding, calendaring, and coating[^8].

Processing Methods:

- Extrusion: Continuous shapes like hoses.

- Molding: 3D items like toys or seals.

- Calendaring: Rolling into thin sheets.

- Coating: Covering fabrics or surfaces with rubber.

What Is Molding Manufacturing Process?

Molding involves shaping materials by introducing them into a mold[^9] where they solidify into the desired form.

Types of Molding:

- Injection Molding: Molten material forced into molds.

- Compression Molding: Material pressed into shape.

- Transfer Molding: Hybrid of injection and compression.

What Is the Method of Fabrication of Rubber?

Common fabrication methods include molding, extrusion, and calendaring[^10], each suited to different product types.

Fabrication Techniques:

- Molding: For complex shapes.

- Extrusion: For tubing and profiles.

- Calendaring: For sheets and coatings.

What Chemical Process Is Used to Make Rubber?

Vulcanization is the key chemical process[^11], involving sulfur and heat to strengthen rubber.

Vulcanization Details:

- Cross-Linking: Sulfur bonds increase strength.

- Improved Properties: Boosts elasticity and durability.

- Applications: Tires, seals, toys.

What Is the Raw Material for Rubber Molding?

Raw materials include natural rubber and synthetic rubbers like EPDM, SBR, and NBR[^12].

Material Types:

- Natural Rubber: Harvested from rubber trees.

- Synthetic Rubber: Engineered for specific traits.

Conclusion

Rubber ducks combine playful design with industrial precision, blending material science, molding techniques, and creative finishing to create a timeless toy.

[^1]: Discover how injection molding shapes rubber ducks. Query: How are rubber ducks manufactured?

[^2]: Understand rubber molding for toy production. Query: What is the rubber molding process?

[^3]: Learn about the rubber ducky method in debugging. Query: What is rubber ducky debugging?

[^4]: See how rubber hoses are made via extrusion. Query: How is a rubber hose manufactured?

[^5]: Find out why excavators are called rubber ducks. Query: What is rubber duck engineering?

[^6]: Know how long rubber ducks last. Query: How long do rubber ducks last?

[^7]: Explore the rubber manufacturing process. Query: What are the steps to make rubber?

[^8]: Learn the four rubber processing methods. Query: What are rubber processing methods?

[^9]: Understand molding in manufacturing. Query: What is molding process?

[^10]: Find rubber fabrication techniques. Query: What are rubber fabrication methods?

[^11]: Explore vulcanization in rubber production. Query: What is vulcanization?

[^12]: Know raw materials used for rubber molding. Query: What raw material is used in rubber molding?